Application of Design Thinking in Solving a Complex Structural Engineering Problem

DOI 10.5433/1679-0375.2024.v45.51507

Citation Semin., Ciênc. Exatas Tecnol. 2024, v. 45: e51507

Received: 25 September 2024 Received in revised for: 10 November 2024 Accepted: 18 November 2024 Available online: 4 December 2024

Abstract:

Design Thinking (DT) may be understood as a strategic framework for problem-solving, applied to the most diverse areas of knowledge, which strongly stimulates creativity and, consequently, innovation. Since structural engineering is often characterized by the solitary and individualistic work of structural engineers, the present work aims to present the main characteristics of DT applied to this specific area, thus stimulating a collective work process. Given that DT is a highly interactive process, this approach is always guided by collaboration, experimentation and empathy. In this way, when there is a meeting of professionals with diverse backgrounds working together, there is a complementation of knowledge, which stimulates the creation of better answers than would be obtained individually. Thus, in order to illustrate the potential of DT, a complex structural engineering problem was selected to apply this approach. It can be concluded that the use of DT, combined with specific knowledge, enabled the attainment of an economic, efficient and creative solution for an extremely emergency situation.

Keywords: Design Thinking, structural engineering, foundations, structural strengthening

Introduction

According to Souza, 2020, structural engineering is a professional activity that has a strong correlation between science and art. To obtain attractive structures, a harmonious combination of sensitivity (creative process) and technical knowledge (critical process) is necessary. Thus, by maximizing this connection in search of the optimal solution, the aesthetic harmony of structures tends to be accompanied by savings of resources, a reduction of execution time, as well as a simultaneous guarantee of the trinomial of resistance, stability, and durability.

Christian Menn, a renowned structural engineer who drew attention to the design of his bridges, revealed in an interview with Whitehead, 2020 that structural engineering seemed to lie between these two opposite poles: science and art. While science is more exact and static, art appears to be more flexible and dynamic. Thus, the mixture of both could result in something like a “more spontaneous science” or a “science with a soul”.

Miret, 1958, recognized for his distinctive structural design, has long wondered whether the resolution of a structural problem could be the result of a purely imaginative process or the result of logical reasoning acquired from some technical training. The eminent Spanish engineer concluded that the answer was a mixture of both: imagination alone would not be able to achieve any result without the help of reason, nor could a deductive process be so logical as not to rely on imagination.

Nervi, 1957, an architect and structural engineer admired worldwide for his beautiful structure designs, believed in a mysterious connection between the laws of physics and aesthetic sensitivity. The structural engineer should work on this connection in the initial phase of structural design, in which individual problems are addressed without formal bias and with the recruitment of intuition.

Félix Candela, an architect and structural engineer renowned for his more than 800 works in hyperbolic paraboloids, used to insistently criticize the analytical procedures employed to calculate the shells in reinforced concrete (Alanís, 2010). In his opinion, procedures based on the Theory of Elasticity produced complex and ineffective routines. He preferred to work on the shape eliminating bending. In addition, Candela used his intuition in parallel with simplified equations based on balance (Martínez, 2018) or the beam model (Martínez, 2019).

Souza, 2020, bringing the process of structural composition closer to musical composition, reveals that the procedures for composing a song or conceiving a structure are very similar. In his opinion, just as the chords are the same for all musicians, the structural elements are the same for all structural engineers. However, how this information is arranged differentiates the inspired artist from the conventional professional.

Thus, knowing the way of thinking of countless inspiring engineers, who can be considered structural artists, the following question arises: Is there any methodology capable of helping conventional engineers achieve this broader vision? Fortunately, the answer is positive and one of the alternatives is the application of Design Thinking (DT), a framework (a set of strategies and actions aimed at solving a problem) for critical, creative, and collaborative thinking that has its roots at Stanford University (McCarthy, 2020).

Buchanan, 1992 changed the concept of design, extrapolating its use in industrial production and revealing its applicability in other sectors and situations. Such innovation was achieved by considering design no longer as an area but as an action, a verb, an attitude, or better defined, DT.

DT has received much attention in recent years, considering its applicability not only to design, but also to several other fields of knowledge. However, its definition has not been fully consolidated, as illustrated by the works of Simon, 1969, Schön, 1983, Lawson, 2006, Brown, 2009, and Martin, 2009.

According to Mosquera et al., 2002, Design Thinking is an approach aimed at solving complex problems, usually classified as “wicked problems” or “complex problems”. Because it is a collaborative and people-focused process, the approach provides perceptible benefits by fostering empathy between all those involved in a project or task and by foreseeing people’s needs before defining a solution. Online collaborative platforms, popularized during the pandemic (Miro, FigJam, and Google JamBoard for example) can help individuals to work together on certain tasks from various locations facilitating a process.

Thus, to illustrate the potential of DT as a tool to help solve complex problems, a critical case of structural stability was selected, in which the urgency of response and interaction between several professionals was necessary. As will be seen below, applying the strategies suggested by DT enabled great involvement on the part of the participants, culminating in a consensual solution characterized by the safety and economic viability required by the client.

Materials and methods

The research was carried out using the practical application of DT in a field problem in structural engineering, which can be considered a “wicked problem”. According to Rittel & Webber, 1973, “wicked problems” or “complex problems” are difficult to solve because they present incomplete, contradictory, and changeable requirements and no single solution. These problems have some important properties, namely:

They have a unique nature and do not have a definitive formulation;

The solutions are not true or false, but only good or bad;

In solving these problems, there is no exhaustive list of admissible operations;

There are no stopping rules and there is always more than one possible explanation, with explanations depending on the designer’s worldview;

It usually stems from another problem and no formulation and/or solution has a definitive test;

Solving a “wicked problem” or “complex problem” is a “one shot” operation, that is, a “single attempt”, since there is no opportunity to learn through trial and error.

Therefore, to apply the DT techniques, a “Case Study” considered a “complex problem” with the following characteristics was selected: the urgency of solution given the critical state of a large structure, high financial losses because the structure under analysis was damaging production and at risk of collapse, different personal interests about the final answer to the problem, complexity in obtaining a solution that would satisfy everyone involved, the divergence of opinions due to different formations and backgrounds, search for the optimal solution to the problem minimizing time/financial resources and guaranteeing the required safety with the application of a single attempt (structural reinforcement).

Techniques and tools such as bibliographical research, documentary research, interviews with those involved in solving the selected problem, and the formation of working groups to apply TD techniques were used to obtain information on the practical problem.

Since DT is a highly interactive process in which building to think is prioritized (Mosquera et al., 2002), we then tried to organize the select group of professionals through successive face-to-face and online meetings so that they could present their ideas about the problem to be solved. Thus, the approach was guided by collaboration, experimentation, and empathy (Koppen & Meinel, 2015), consolidating the idea that when different people with diverse minds build together, and the complementation of knowledge takes place, which stimulates innovation. Although DT strategies can also be conducted individually, in our case, the interaction of several professionals was inevitable due to the complexity and consequent multiplicity of interests.

The working group for the structural stabilization of the selected building included the following professionals: an expert in numerical modeling of complex structures, an expert in silo design, an expert in structural reinforcement design, an expert in management, an expert in non-destructive testing, an expert in cement production, a representative of the board of directors of the former owner of the selected structure (an international company that is among the largest cement producers in the world) and a director of the current owner of the selected structure (a national company of international expression, leader in the steel, mining, logistics, cement, and energy industries).

The activities followed the flow proposed for DT, according to Vianna et al., 2013:

Immersion: This is the first phase of the process, at which point the team approaches the problem not only from the client’s point of view but also from the point of view of all the stakeholders. At this stage, it is common to resort to scientific research, field investigations, interviews, and collection of the most diverse information necessary for in-depth interaction with the problem to be solved;

Analysis and synthesis: After obtaining and organizing all data deemed relevant, the team must seek to analyze it to recognize patterns and relationships through collaborative meetings. At this stage, the perceptions of those involved arise for the development of solutions;

Ideation: Based on the perceptions obtained by the team in the previous phase, creativity is then stimulated through brainstorming sessions or other techniques, aiming at the generation of a variety of solutions in the context of the problem addressed. At this stage, the participation of people with different backgrounds is very important, which is why the formation of a multidisciplinary team is encouraged.

Prototyping/testing: They must be validated by taking them from the abstract world to the real world by creating solutions. Depending on their need, these prototypes can present low, intermediate or high fidelity. That is, they can go from a simple paper model to the actual idealized model itself;

Implementation: the last phase of the process consists of testing the prototypes created, by seeking to improve them. Thus, the previous steps can be repeated to make changes or even create alternative solutions. The ultimate goal of this stage is an in-depth understanding of the product and its users.

Results and discussion

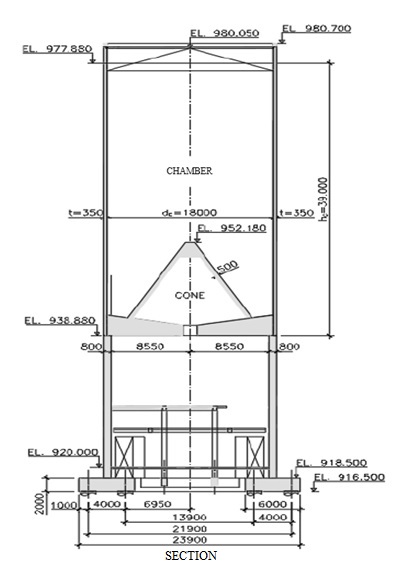

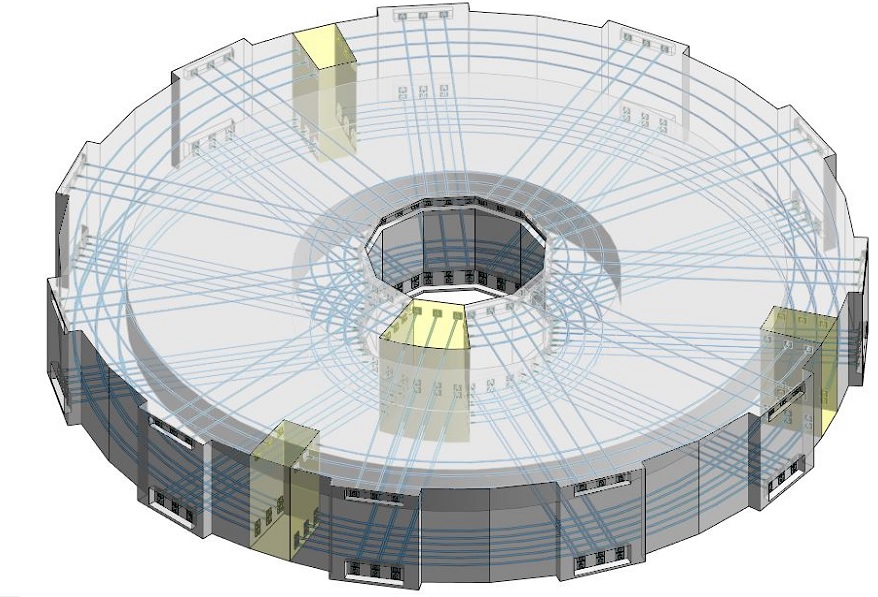

In order to illustrate the application of DT to structural engineering, a structural problem that can be considered highly complex was selected, thus requiring the collaboration of several professionals. For this purpose, the silo illustrated in Figure 1 was selected, with a cement storage volume of \(8,000~\text{m}^3\) (about \(10,000\) tons of cement, which alone represents approximately R$ 6,000,000.00), built in reinforced concrete and at risk of collapse due to the occurrence of significant settlements, the details of which are presented below.

| (a) | (b) |

|  |

The concrete structure of the silo in question has a total height of \(62\) m, an external diameter of \(18.70\) m, and an internal diameter ranging from \(18\) m (chamber area) to \(17.10\) m in the stretch between elevations EL \(938.880\) and EL \(918.500\) (top of the foundation block) as illustrated in Figure 1(a). The walls of the silo are \(35\) cm thick from elevations EL \(938.880\) to EL \(977.880\) and \(80\) cm thick from elevations EL \(918.500\) to EL \(938.880\).

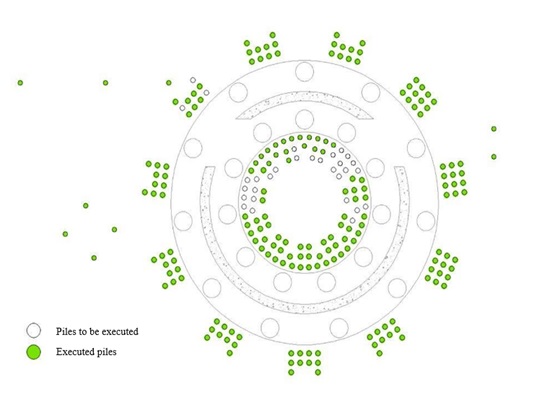

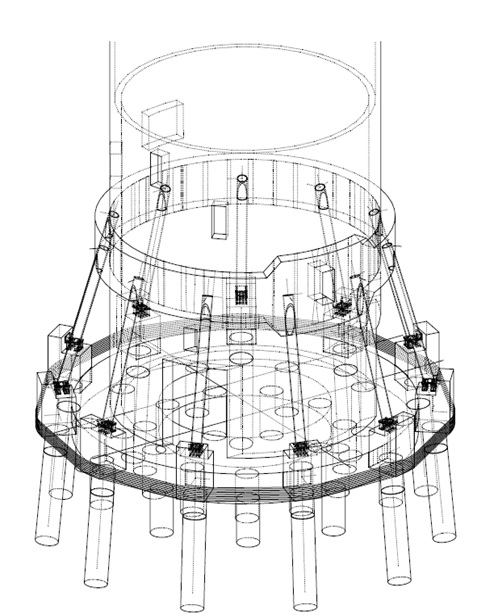

The silo structure is built on a \(2.0\) m high ring foundation pile cap with \(23.90\) m external diameter and \(11.90\) m internal diameter, and it is supported by \(22\) piles as illustrated in Figure 1(b). The piles defined in the project are of the excavated type, with a \(160\) cm diameter and variable length (estimated depth of \(17.2\) m), and they should have complied with a minimum embedment equal to the diameter of the piles in the bedrock in the area where the silo is located.

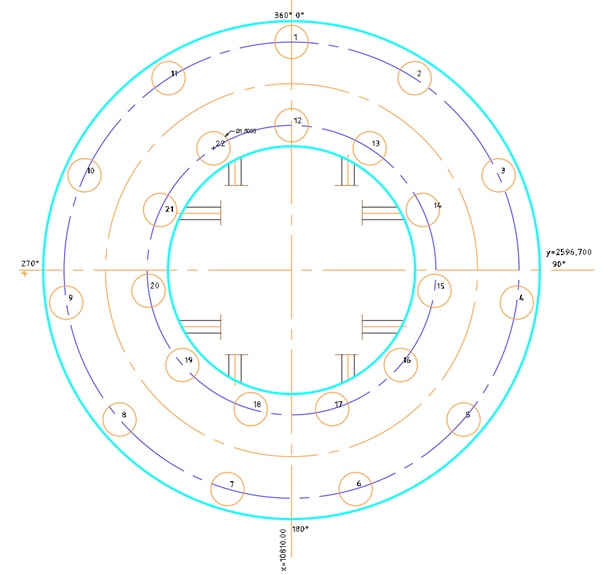

However, of the \(22\) piles in the ring pile cap, only one pile had been properly embedded in rock, so significant settlements occurred and led to a significant displacement at the top of the silo shown in Figure 2(a). Measurements pointed to a displacement at the top of the silo of \(46.9\) cm, including a constructive misalignment around \(5.0\) cm. Thus, slopes exceeded the maximum values established in the European standard EN 1997-1:2004. In addition, numerical modeling, as shown in Figure 2(b), showed that more intense winds could generate significant stresses on the foundations, which could cause the silo to collapse.

| (a) | (b) |

|  |

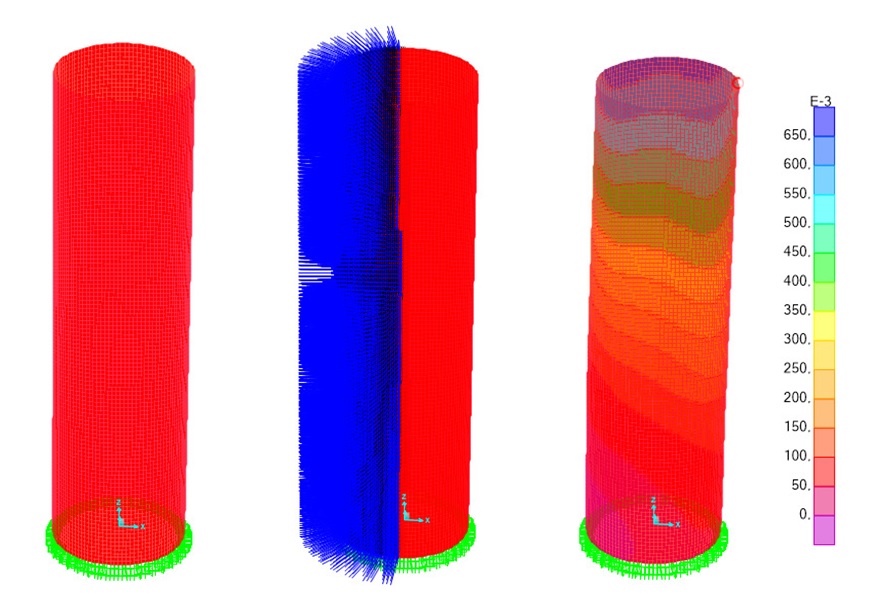

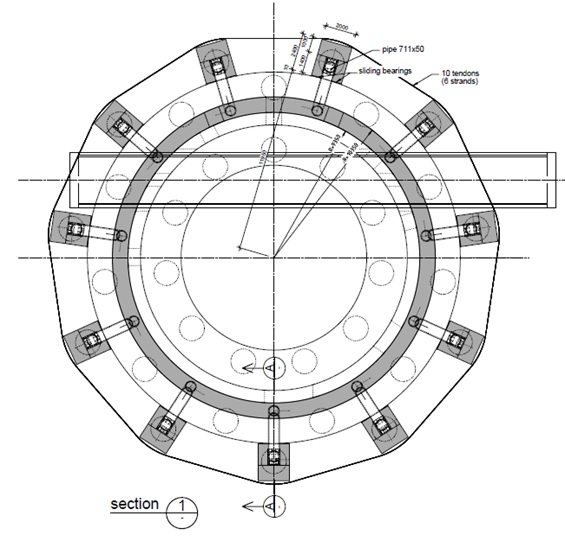

As a result, a very well-designed foundation strengthening design was developed by one of the silo owner’s contractors, as illustrated in Figure 3(a). The project prescribed polyurethane and microconcrete injections into the soil to temporarily increase the efficiency of the piles in soft soil. The execution of new piles anchored in rock, the execution of a prestressed inner/outer ring, and radial prestressing bands to consolidate the original ring pile cap to the proposed strengthening. Figure 3(b) shows a three-dimensional view of the proposed strengthening.

| (a) | (b) |

|  |

However, even after all the injections made into the soil (much higher consumption than initially predicted, indicating the probable presence of caves in the geology of the site), in order to temporarily stabilize the floating piles in soft soil, new settlements were observed during the driving of the final reinforcement piles, see Figure 4, which led to the need for immediate interruption of services. The additional settlements generated an additional displacement at the top of the silo of \(14.7\) cm, resulting in a total lateral displacement of approximately \(61.6\) cm.

In view of these unexpected new settlements, the current owner of the silo called on numerous professionals from a wide range of fields and backgrounds to define a complementary reinforcement solution, aiming to resume the originally proposed reinforcement safely. Within this context, an approach began in which the DT was of great value to reach an optimal solution, always based on the three pillars of the method: practicability, feasibility, and desirability.

The first measure taken after the occurrence of the new settlements was to bring together all the experts for a face-to-face meeting at the silo facilities so that everyone would know the real situation and urgency. Within the DT, this phase can be considered the “Immersion Stage” and was fundamental for insight stimulation and convergence of ideas in the team. The vast majority of the experts involved, external to the former and the current owners of the silo, were already well aware of the technical reports, and the reinforcement proposal, but had never been on site.

Walking around the environment of the affected silo, a very productive field was opened for discussions on the reasons why new settlements were occurring, despite the injections made into the soft soil. The presence of underground caves was considered due to the volume of polyurethane consumed being much larger than the projected injection volume, as well as the effect of vibrations introduced into the original piles as a result of the staking process of the root-type reinforcement piles. Thus began the “Synthesis Analysis Stage”, with the organization and discussion of the available data and the refinement of the perceptions obtained in the field.

There was unanimous agreement to resume the initial plan: the original reinforcement activities had to be halted and an interim reinforcement should be devised. Thus, the “Ideation Stage” began, and the first situation discussed by the group was the resumption of a previous proposal established by a German company, which consisted of installing metal profiles externally anchoring the silo. Figure 5(a) shows the plan view of the idea while Figure 5(b) shows a three-dimensional view.

As the external piles were already in place, the German project could be resumed, requiring only metal profiles and the installation of an upper ring for the connection between the foundations and the silo body. However, although the idea persisted for some time, it was a very expensive and difficult intervention due to the giant metallic ring being installed at a great height. In addition, the installation of the proposal reflected architecturally and also functionally, since it would limit the entry of vehicles into the silo.

| (a) | (b) |

|  |

Abandoning the German idea of strengthening, it was then considered a series of tie rods anchored to the body of the silo and a series of temporary foundation blocks. Although it seemed an interesting idea, the diameter of the cables would be extremely high and such reinforcement would introduce major difficulties in determining the effective stresses acting on the cables and the silo, thus leading to a highly non-linear problem. The mathematical and installation complexity thus ended up eliminating this idea, which was both so simple and so complex.

Back in the field, due to the late arrival of the representatives of the owner and the former owner of the silo (return to the immersion, analysis and synthesis, and ideation phases), an insight emerged and referred to a solution that was simple to calculate and easily feasible: the installation of a counterweight on the opposite side of the silo where the settlement had occurred. There was, thus, unanimity that such an idea would be the best among the possibilities raised, but it would need to be analyzed and quantified over the coming weeks of work.

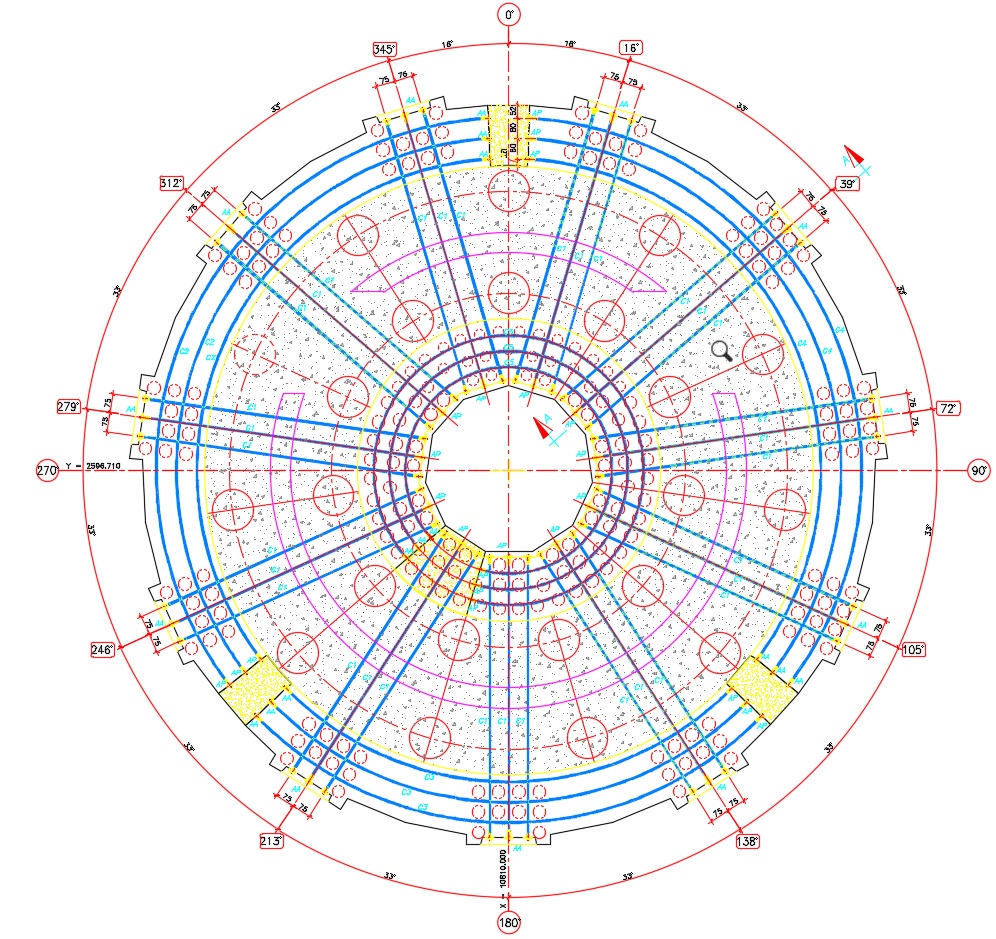

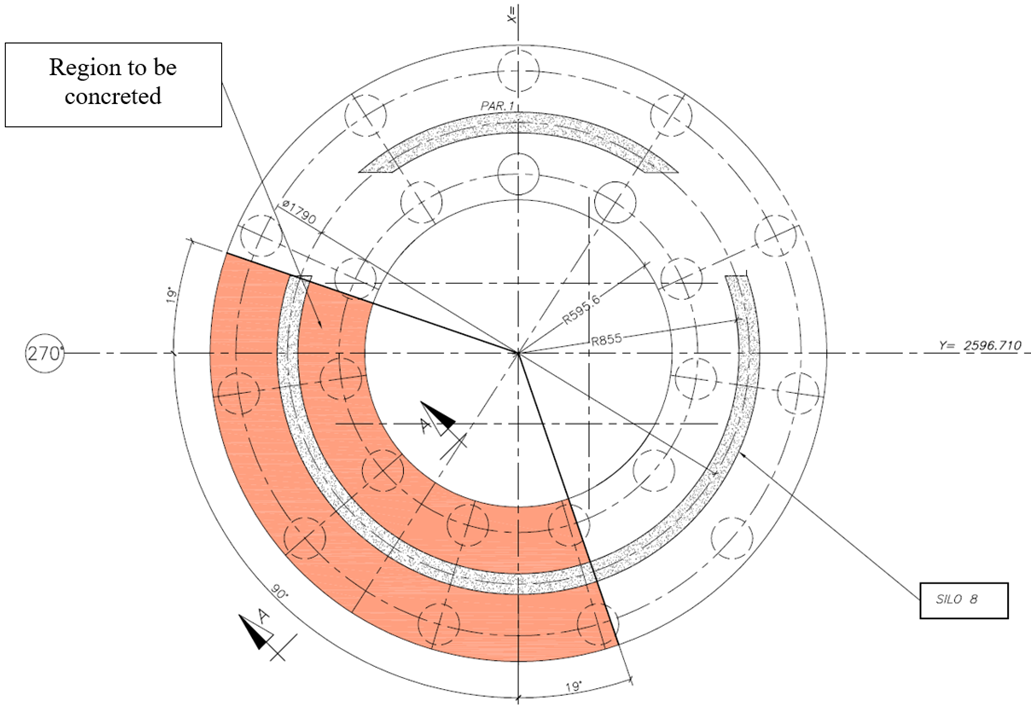

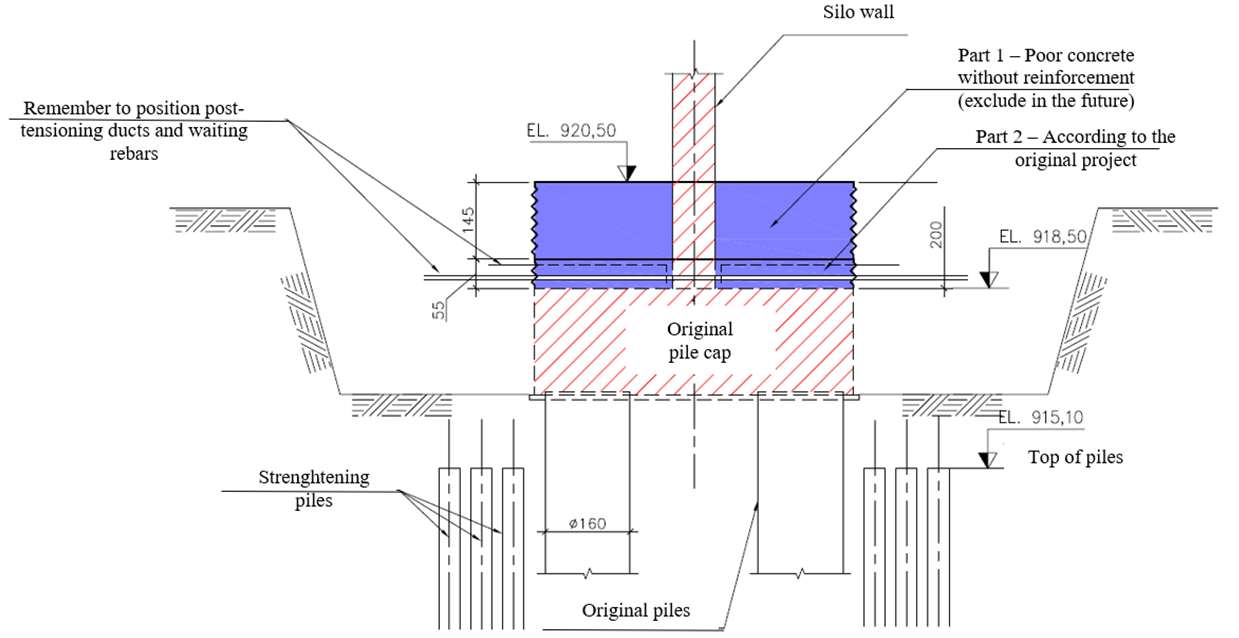

It was the start of the “Prototyping and Testing Stage” conducted by the structural calculation experts. The problem consisted in establishing the height of the counterweight and an appropriate safety factor in relation to stability, considering the settlements that occurred, as well as the winds acting on the body of the silo. Thus, after numerous discussions and conferences, weeks after the face-to-face meeting, the prototype illustrated in Figure 6 was created. Figure 6(a) shows a plan view while Figure 6(b) shows a section detail of the proposal.

(a)

(b)

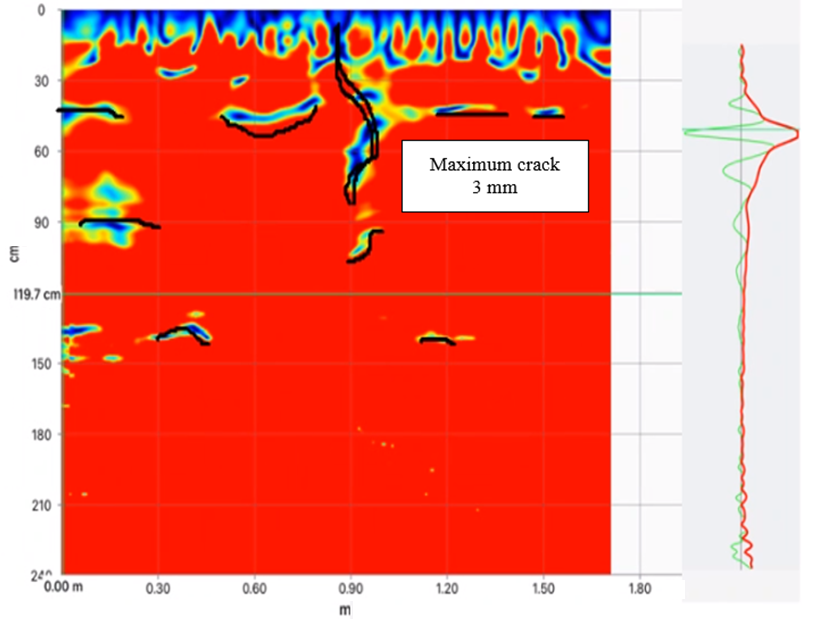

Although the proposal of strengthening using the counterweight offered the necessary safety, representatives of the companies involved decided that an extra reinforcement solution had to be implemented. This decision was made after a vertical crack of \(3\) mm was identified in the section of the original foundation ring pile cap subjected to settlement while the counterweight construction operations were carried out. The crack was identified using GPR (Ground Penetrating Radar) equipment, as illustrated in Figure 7.

Although the technical team concluded that this crack was more due to the original construction process than the settlements, the companies’ representatives involved decided that extra reinforcement would still be necessary. Thus, a return to the “Ideation Stage” was established to meet the required degree of safety. Evidently, throughout the process, the stages of immersion, analysis, and synthesis always ran in parallel so that better solutions could emerge in the ideation and, consequently, prototyping and testing stages.

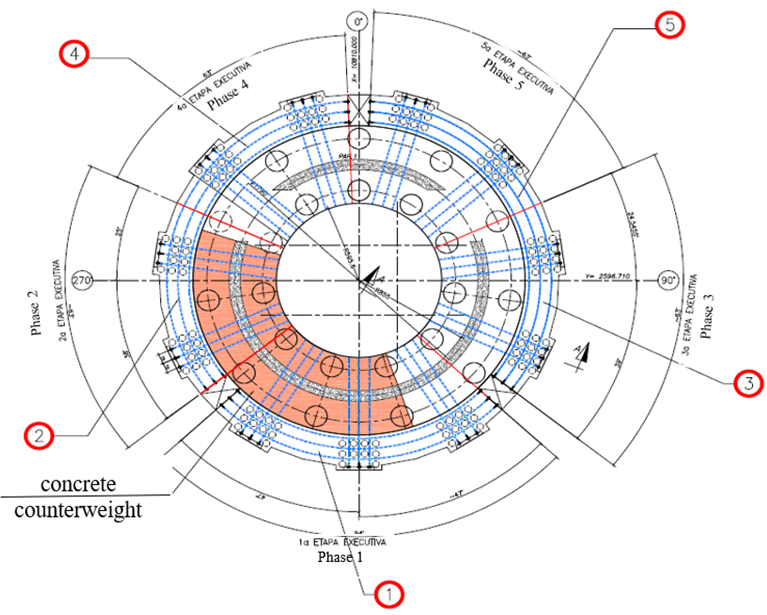

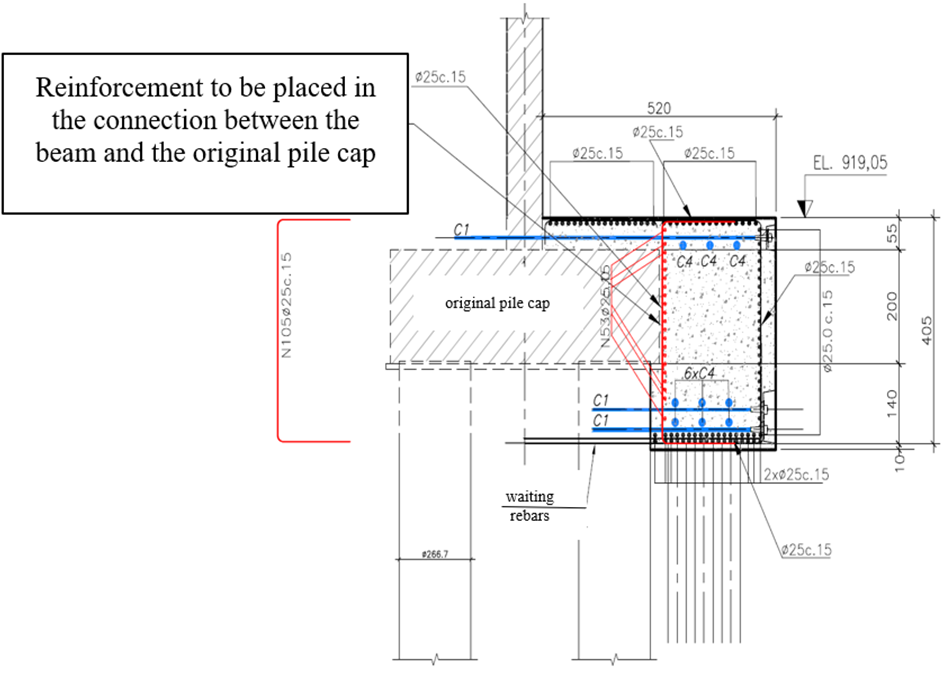

Thus, after numerous discussions, the idea of taking advantage of the reinforcement piles already in place and gradually building the outer ring connected to the original ring pile cap through connecting bars at the interface (new “Prototyping and Testing Stage” according to DT) survived, as shown in Phases 1 to 5 presented in Figure 8(a). Basically, shear pins capable of absorbing the total weight of the silo between the interfaces were conceived in the critical settlement area, thus mobilizing the new foundations in the event of settlements in the old piles due to potential counterweight deficiency, as shown in Figure 8(b).

(a)

(b)

Once the “Prototyping and Testing Stage” was completed, both for the counterweight and the interface pins, the final DT stage, namely the “Implementation Stage” initiated.

Figure 9 illustrates the construction of the outer portion of the counterweight (operation completed in January 2023), while Figure 10 illustrates the installation of the interface pins between the original foundation ring and the outer strengthening ring (operation completed in April 2023).

As a result of the activities assisted by the DT techniques, it was possible to obtain a much more economical, mathematically simple, and reliable reinforcement solution. The temporary strengthening solutions made it possible to resume the driving work of the missing reinforcement piles, thus enabling the safe restart of the original strengthening project.

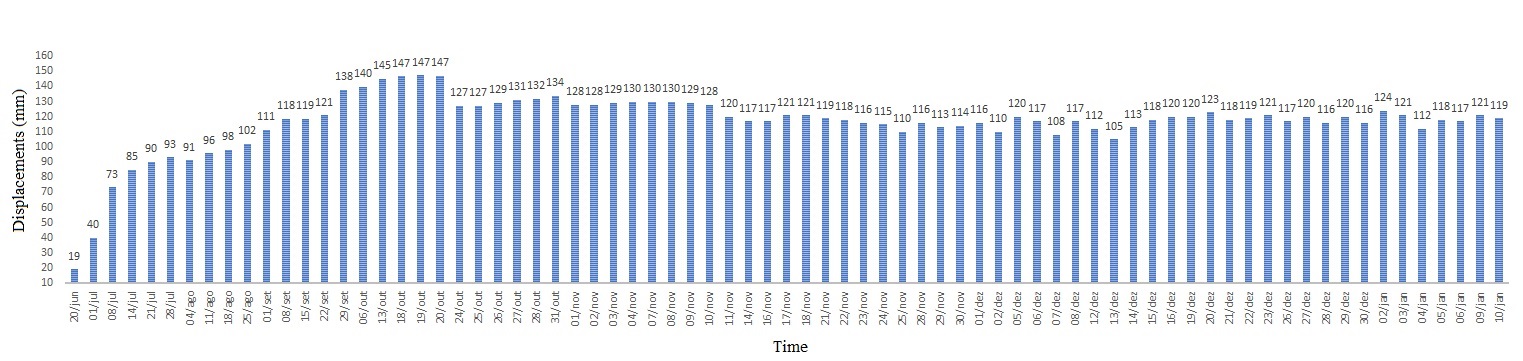

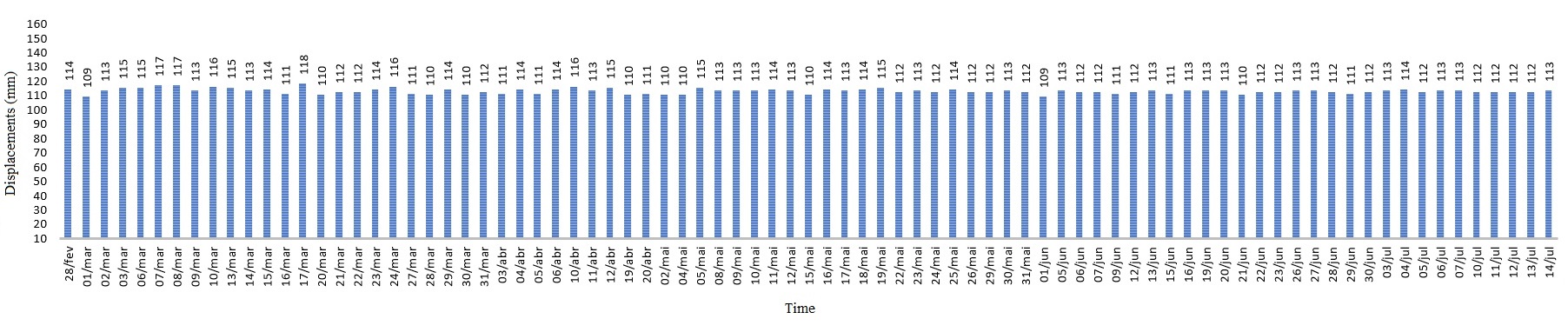

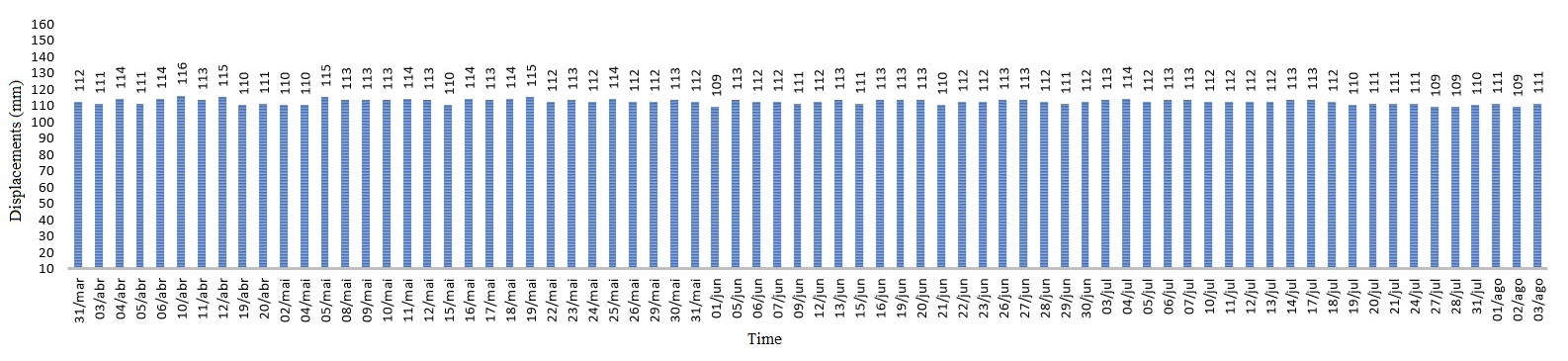

Figure 11(b) illustrates that since the end of April 2023, when the two temporary strengthening solutions designed with the aid of DT were finalized, the top of the silo has clearly stabilized. It can be observed that, for the period from June 2022 to January 2023, the displacements at the top of the silo oscillated a lot as shown in Figure 11(a). However, in January 2023, with the construction of the counterweight, much milder movements were verified. Figure 11(c) shows the top stabilized top displacements from May/2023 to September/2023.

| (a) |

|

| (b) |

|

| (c) |

|

Figure 12 shows that the collapse of the silo in the direction of settlement could lead to the collapse of smaller buildings, as well as elevated platforms, generating even more damage than the collapse of the silo itself. For this reason, throughout the intervention, the top displacement of the silo was constantly monitored with the aid of an anemometer, with the immediate sounding of sirens for winds exceeding 50 km/h.

Conclusions

This work aimed to present the main characteristics of Design Thinking, a support tool for solving complex problems in any area of knowledge. Therefore, a cement storage silo in a critical stability situation due to significant settlements was selected as the critical problem for applying this framework.

With the help of the classic stages proposed by Design Thinking, it was possible to develop effective complementary strengthening solutions to stabilize the silo promptly, thus enabling personnel to safely return to the field to complete the original strengthening activities of the compromised structure.

Based on the selected problem, solutions obtained with the aid of Design Thinking are truly surprising, characterizing the tool as an important apparatus for the specific training of stakeholders. Through this strategic, interactive, and rational approach, it is possible to achieve a more consistent workflow, thus facilitating the achievement of more creative and collaborative solutions to complex problems of any nature.

Acknowledgments

I would like to express my deepest gratitude to the individuals and institutions whose support this paper, in special Polytechnic School of the University of São Paulo, State University of Maringá and Engracon Structural Engineering.

Author contributions

R. A. de Souza participated in: Conceptualization, Formal Analysis, Investigation, Methodology, Writing – original draft.

Conflicts of interest

The authors certify that no commercial or associative interest represents a conflict of interest concerning the manuscript.

References

Alanís, E. X. A. (2010). Candela. Editora Taschen, Koln.

Brown, T. (2009). Change by Design: How Design Thinking Transforms Organization and Inspires Innovation. Harper Collins.

Buchanan, R. (1992). Wicked Problems in Design Thinking. 8(2), 5--21. https://doi.org/10.2307/1511637

Lawson, B. (2006). How Designers Think. Elsevier.

Koppen, E. & Meinel, C. (2015). Empathy via Design Thinking: Creation of Sense and Knowledge, Understanding Innovation. Springer. 15--28.

Martin, R. (2009). The Design of Business: Why Design Thinking is the Next Competitive Advantage. Harvard Business Press.

Martínez, Mónica Martínez (2018). Proceso de cálculo de las cáscaras cilíndricas largas de cubierta en la obra de Félix Candela. El enfoque del equilibrio. 260. https://doi.org/10.3989/ic.56644

Martínez, Mónica Martínez (2019). Application of the beam method to structural calculation of the long cylindrical concrete shells in the work of Felix Candela. 18(1), 134--144. https://doi.org/10.7764/RDLC.18.1.134

Miret, E. T. (1958). Las Estructuras de Eduardo Torroja. Centro de Estudios y Experimentación de Obras Públicas.

McCarthy, S. (2020). Design at Stanford: the D.school’s Daddy. CRC Press. 207--210. https://doi.org/10.1201/9781003046103

Mosquera, R., Pires, C., Santos, M. & Orofino, M. A. (2002). A Jornada Ágil: Um Caminho para a Inovação. Editora DVS.

Nervi, P. L. (1957). The Importance of Construction Technique. 6(1), 6--12.

Rittel, H. W. J. & Webber, M. M. (1973). Dilemmas in a General Theory of Planning. 4(2), 155--169.

Schön, D. (1983). The Reflective Practitioner: How Professionals Think in Action. Basic Book.

Simon, H. A. (1969). The Sciences of the Artificial. MIT Press.

Souza, R. A. (2020). Em Frente ao Buriti: Reflexões de Um Engenheiro de Estruturas. SGuerra Design.

Vianna, M., Vianna, Y., Adler, I. K., Lucena, B. & Russo, B. (2013). Design Thinking Business Innovation. MJV Press.

Whitehead, R. (2020). Structures by Design: Thinking, Making, Breaking. Taylor & Francis.