A Study of Chinese and Japanese Porcelains fromArchaeological Sites of Mexico City, Using INAA

DOI 10.5433/1679-0375.2024.v45.50614

Citation Semin., Ciênc. Exatas Tecnol. 2024, v. 45: e50614

Received: 16 May 2024 Received in revised for: 17 June 2024 Accepted: 21 June 2024 Available online: 7 August 2024

Abstract:

This study analyzes porcelain fragments unearthed at multiple archaeological sites in Mexico City, formerly known as New Spain. A collection of 60 samples was successfully categorized into four different groups and analyzed based on the Instrumental Neutron Activation Analysis (INAA) in conjunction with statistical methods. One of the groups included blue-and-white porcelains, which conclusively traced back to the renowned Jingdezhen kilns. Another blue-and-white group was attributed to the Zhangzhou kilns. Notably, it was determined that the Chinese white porcelains, distinguished by their low iron content, originated from the Dehua kilns. In contrast to Chinese porcelain, a separate category was identified as Japanese porcelain, which displayed distinct chemical signatures. These Japanese pieces were probably sourced from the Arita kilns. The origin of the two porcelain bodies remained elusive and undetermined throughout our analysis. The chemical analysis of archaeological specimens provides invaluable data on their identity and provenance. Therefore, the findings presented here offer compelling evidence of extensive trade, cultural, and social connections between China, Japan, the Philippines, and Mexico City during the Viceroyalty period facilitated by La Nao de La China (The China Ships).

Keywords: chinese porcelains, japanese porcelain, INAA, statistical analysis

Introduction

Porcelain, a renowned glazed whiteware, originated in China, where it served as both utilitarian dinnerware and exquisite art pieces. Notably, the famous blue-and-white porcelain has its roots in Jingdezhen, located in the Jiangxi province, where production began during the Yuan Dynasty (1280–1368 AD). These exquisite items were distributed to neighboring nations from that era onward.

During the subsequent Ming Dynasty (1368–1644 AD), two noteworthy changes occurred: a notable improvement in the quality of Chinese porcelain and an expansion of maritime trade connections.

The production of high-quality blue-and-white porcelain thrived, and from the 17\(^{th}\) to the 18\(^{th}\) centuries, various maritime enterprises transported vast quantities of these sought-after ceramics to Europe (Dillon, 2008).

In 1565, Miguel López Legazpi and Fray Andrés de Urdaneta initiated the China Nao Route. Fray Andrés de Urdaneta adeptly determined the return route by navigating the Kuro Shivo current until reaching the northern coast of California. Subsequently, they followed the coastline, eventually arriving at the port of Acapulco. This coastal navigation allowed for strategic stops at ports such as San Blas for refueling and trading activities (Mejia & Mejia, 2022; Kuwayama, 1997).

Furthermore, other kilns, such as those in Zhangzhou in Fujian province, began crafting blue-and-white porcelain for export. However, these wares did not achieve the same level of quality as those produced in Jingdezhen due to variations in production techniques and designs (Min, 2013).

Distinct from the blue-and-white counterparts, white Chinese porcelain, also referred to as "blanc de Chine" or "ivory white," was predominantly crafted in the Dehua kilns during the Ming Dynasty. This high-quality white porcelain found extensive markets in both Europe and America, contributing to substantial exports (Kerr & Ayers, 2002).

Chinese porcelain maintained a monopoly in Japan until the late 16\(^{th}\) century when Korean potters began the production of porcelain in the Hizen province, which is now part of the Saga and Nagasaki prefectures. From that point forward, Japan actively participated in the porcelain trade, initially drawing inspiration from Korean and Chinese traditions before gradually developing its distinct quality and designs (Nagatake, 2003). The term "Arita ware" is derived from the town where it was manufactured, while "Imari ware" refers to the adjacent port through which it was shipped.

Porcelain, primarily composed of kaolin, incorporates materials such as quartz, clays, and feldspar, influencing its chemical makeup (Sterba et al., 2009).

Diverse manufacturing techniques, influenced by ceramists and available materials, are utilized in the creation of ceramics, including porcelain. Relying solely on typology and decorative features may fall short in classifying porcelain artifacts. As a result, there has been a notable surge in interest regarding the quantification of both major and minor elements found in these ceramics.

Conducting chemical analyses is essential for a comprehensive examination of ceramics, and in this regard, neutron activation analysis emerges as an optimal method. The scrutiny of Chinese porcelain has garnered considerable attention in previous research .

These studies have covered a range of dynasties, including the Yuan, Ming, and Qing dynasties, as well as diverse kilns such as Dapu, Jingdezhen, Zhangzhou, Dehua, and Fengdongyan, among others. They have explored various raw materials and intricate production techniques. The chemical composition of porcelain is complex and connected to these factors. While the primary elements in porcelain demonstrate relatively stable characteristics that mirror the geological properties of the clays employed, the concentration of trace elements can vary significantly and frequently serves as a distinctive feature for identifying the origin of the porcelain.

Research focusing on the chemical analysis of Japanese porcelain is comparatively less prevalent than studies on Chinese porcelain. An examination comparing antique white porcelains from Gwangju-si (Korea) and Arita (Japan) drew attention to distinctions attributed to raw material variations (Byungsun, 1999). In another investigation Katsuki et al., 2019, discernible differences were observed among Korean porcelain from the Chosŏn dynasty, Jingdezhen porcelain, and Arita porcelain, although the techniques used were not specified. Notably, the major elemental data for Arita porcelains reported in these studies exhibit remarkable consistency.

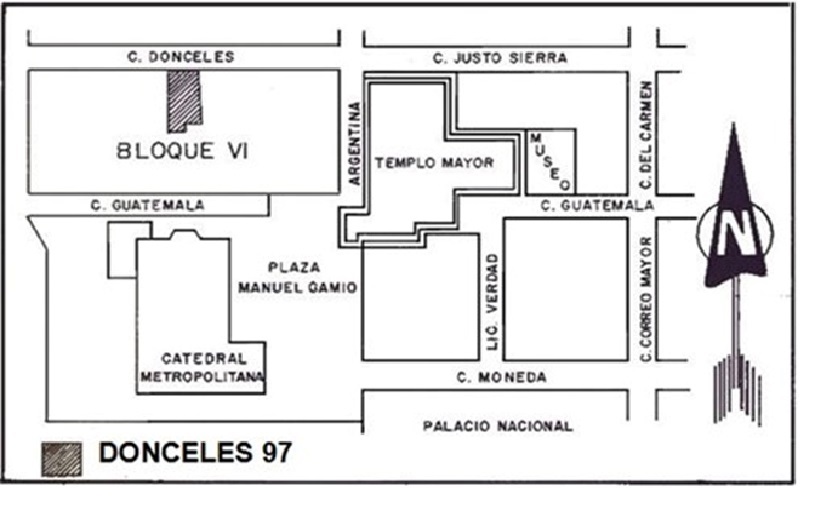

The porcelain fragments examined in this research were discovered beneath archaeological sites within present-day Mexico City’s Historical Center see Figure 1. Most specimens were recovered from a building at 97 Donceles Street. Comprehensive information regarding the historical context of the structure that once occupied this location and excavation details can be found elsewhere Terreros-Espinosa et al., 2021 and Terreros-Espinosa & Moctezuma, 2003. Additionally, other specimens were contributed by the Programa de Arqueología Urbana and the Templo Mayor-Programa de Mejora de la Gestión, originating from various sites in downtown Mexico City.

The presence of Chinese (Fournier & Junco Sanchez, 2019; Fournier & Otis Charlton, 2015; Junco & Fournier, 2008; Kuwayama, 1997; Priyadarshini, 2018) and Japanese (Takenori & Terreros-Espinosa , ) porcelain artifacts in New Spain, now known as Mexico City, has been documented. However, there remains a noticeable gap in research concerning archaeometric analyses aimed at determining their origin or arrival timeframe. Consequently, this groundbreaking investigation has three primary objectives:

Perform an extensive multi-element analysis on a set of porcelain shards retrieved from downtown Mexico City using Instrumental Neutron Activation Analysis (INAA).

Integrate the data derived from these analyses with existing literature to reconstruct information about the geographical origins of the collection.

Contribute significantly to enhancing our comprehension of the sustained trade connections with China and Japan during the Viceroyalty period in Mexico.

Materials and methods

The collection comprises 60 porcelain object fragments, with 10 of them classified as Japanese based on their typology, while the remainder were classified as Chinese. Details about the recovery sites and individual shard descriptions are provided in Table 1.

| Key | Site | Description | Typology | |

|---|---|---|---|---|

| Cluster C1 | ||||

| P1 | (A) | B580 Dish, blue/white. Gorgeous knot, symbol of the heart of Buddha | Jingdezhen | |

| P2 | (B) | - Polychrome dish (1720s) | Chinese | |

| P3 | (C) | LP C4 B5 Polychrome chocolate cup | Jingdezhen | |

| P5 | (A) | B523 Dish, blue/white | Jingdezhen (Tree-Peony Botan) | |

| P7 | (C) | 91 IIJS-33 B318 Cup, blue and white/brown, phytomorphic designs | Jingdezhen | |

| P8 | (C) | II J.S. 33 Chocolate cup, blue outside with golden phytomorphic designs, red phytomorphic designs at the bottom | Chinese | |

| P9 | (C) | G-18 B-54 Cup, multicolor, phytomorphic and geometric designs outside; a blue edging of the swastika inside | Chinese | |

| P10 | (C) | G22 Cup, green phytomorphic designs outside, a green design outlined with black and red inside | Chinese, Ming, green, 1600-1650 | |

| P11 | (A) | B557 Cup, blue/white, zoomorphic and phytomorphic design outside, lines on the inner edge | Jingdezhen, 1620-1640 | |

| P12 | (A) | - Cup, red lines, red and green tips, the green ones outlined with black outside. A seal at the base. | Jingdezhen, 1620-1640 | |

| P13 | (C) | CCE UBE-B18 Cup, blue/white anthropomorphic and phytomorphic designs outside, a circular line on the edge inside | Jingdezhen, 1620-1640 | |

| P14 | (A) | B120 Large bottle, blue/white | Kraak, San Diego shipwreck? | |

| P15 | (A) | B460 Cup, blue/white, phytomorphic designs inside | Kraak | |

| P16 | (A) | B188 Large dish, blue/white, phytomorphic designs inside, geometric design outside, non-glazed base. | Kraak | |

| P17 | (A) | B527 Little cup, blue/white, geometric design outside, the edge of the holder is not glazed. | Jingdezhen, XVII | |

| P18 | (A) | B445 Little cup, blue/white, Taihu design outside, floral designs inside, lobed edge | Jingdezhen, 1573-1620 | |

| P21 | (C) | G18 B22 Cup | Jingdezhen, 17th c | |

| P22 | (C) | G18 B22 Cup | Jingdezhen, 17th c | |

| P23 | (C) | 91 IIJS-33 B23 Cup | Jingdezhen, Late 17th-early 18th c | |

| P24 | (C) | 91 IIJS-33 Cup | Jingdezhen, Late 17th-early 18th c | |

| P25 | (A) | B173 Cup, blue/white, floral designs outside | Jingdezhen, 17th c | |

| P26 | (C) | 91 IIJSB29: Cup, pink flower and golden leaf at the bottom, the outer walls are lobed | Jingdezhen | |

| P27 | (A) | B376 Chocolate cup, blue/white, annular base, the edge is not glazed, two circular lines outside the base | Guangdong, Late 16th c | |

| P52 | (A) | B584 Small cup, blue/white, design outside (snail?), thick and unglazed ring base | Jingdezhen | |

| P53 | (A) | B35 Large dish, blue/white, zoomorphic designs inside, pin holes and lathe tracks | Jingdezhen | |

| P57 | (A) | B140 Dish, blue/white, panels inside, mirror representation at the bottom panel, phytomorphic designs outside, the base is not completely glazed, sand adhesions on the ring holder | Kraak | |

| P58 | (C) | CCE E 8/9 558 Cup, blue/white, anthropomorphic designs outside, base not glazed, pin holes, circular lines inside | Jingdezhen | |

| P60 | (C) | G38 IV-66 Chocolate cup, polychrome, blue line below the everted edge, floral designs in red, blue and gold outside, blue line inside | Jingdezhen | |

| Cluster C2 | ||||

| P31 | (A) | LV2 B-214 Large plate blue/white | Japanese | |

| P32 | (A) | LV2 B-212 Kenyi, blue/white | Japanese | |

| P33 | (A) | LV2 B-212 Chocolate cup, blue/white | Japanese | |

| P34 | (C) | Guat-34 Large plate, blue/white | Japanese | |

| P35 | (C) | Guat-28 C4B1 Dish, blue/white | Japanese | |

| P36 | (C) | 91 IIJS-33 Dish, blue/white | Japanese | |

| P37 | (D) | Rubbish dump-V Chocolate cup, blue/white | Japanese | |

| P38 | (A) | LV2 B212 Large plate, blue/white | Japanese | |

| P39 | (D) | Rubbish dump-V Chocolate cup, polychrome | Japanese (cherry flower) | |

| P40 | (D) | Rubbish dump-V Chocolate cup, polychrome | Japanese | |

| Cluster C3 | ||||

| P41 | (D) | Rubbish dump-V Small cup | Dehua, 18th c | |

| P42 | (A) | B- Cup, eight lobes, smooth sides | Dehua | |

| P43 | (A) | B- Chocolate cup lobed and smooth sides | Dehua | |

| P44 | (C) | LP 64-65 Fragment of the base of a Buddhist Lion incense stick holder. Late Ming or early Qing dynasty, ca. 1640-1660. From Lic. Verdad Street -Block III, in Museo del Templo Mayor (INAH) | Dehua | |

| P45 | (C) | B-6 Lid, phytomorphic designs | Dehua | |

| P46 | (A) | B-273 Cup, phytomorphic designs | Dehua | |

| P47 | (A) | B-106 Chocolate cup, phytomorphic designs | Dehua | |

| P48 | (A) | - Chocolate cup, phytomorphic designs, cracked glaze | Dehua | |

| P49 | - | SPN/CAT-M-RA Dish? phytomorphic designs, cracked glaze | Dehua | |

| Cluster C4 | ||||

| P4 | (C) | LP C7 B2 Polychrome dish | Chinese | |

| P6 | (C) | 91 IIJS-33 B2 Small cup, white/brown, phytomorphic designs | Chinese | |

| P19 | (D) | Rubbish dump-V Chocolate cup, blue/white, phytomorphic designs inside, thick, unglazed ring holder | Zhangzhou | |

| P20 | (C) | G Large dish, blue, white points. | Zhangzhou | |

| P28 | (A) | B470 Chocolate cup, blue/white, annular base, the edge is not glazed, floral design at the bottom, a circular line outside the base, the glaze is cracked | Guangdong, Late 18th c | |

| P29 | (A) | E667 Porcelain fragment with a Buddha representation | Chinese | |

| P30 | (A) | - Phytomorphic kettle handle | Chinese | |

| P54 | (C) | PAL B25 Large dish, blue/white, geometric designs at the inside molding, vertical corrugated lines at the outside molding, crackled glaze | Zhangzhou | |

| P55 | (C) | BVII AN B12 Cup, blue/white, phytomorphic designs at the bottom, lines outside, holder and base not completely glazed, sand adhesions on the ring holder | Zhangzhou | |

| P56 | (C) | BVII AN B3 Cup, blue/white, phytomorphic designs at the bottom, holder, and base, not completely glazed, sand adhesions on the ring holder | Zhangzhou | |

| P59 | (C) | CCE U-60 B.2 Large dish, blue/white, phytomorphic designs and circular lines inside, cracked surfaces, blue circular line, holes pin, and sand adhesions on the ring holder | Zhangzhou | |

| P50 | (C) | G38 V-105 Cup, blue/white, phytomorphic designs | Zhangzhou | |

| P51 | (A) | B5 Small cup, polychrome, red border on the edge and polychrome phytomorphic designs inside | Chinese, 18th c | |

After carefully removing the glasses using a tungsten drill bit, the porcelain bodies, underwent grinding using an electric agate mortar, and the resulting powders were subsequently dried at 80°C for 24 hours. These prepared samples, amounting to 200 mg each, were then subjected to a two-hour irradiation process within the Triga Mark III nuclear reactor located at the Nuclear Center of Mexico. This irradiation took place under the influence of a thermal neutron flux measuring 1\(\times\)10\(^{13}\) cm\(^{-2}\) s\(^{-1}\). Reference materials, specifically SRM 278—Obsidian Rock from the National Institute of Standards and Technology and Ancient Chinese Ceramic (Shakhashiro et al., 2006) were concurrently irradiated alongside the archaeological samples.

Subsequent measurements of both the samples and reference materials occurred after a decay period of 10–12 days, with each measurement lasting 2 hours. The gamma detection system consisted of an HPGe detector (GEM 40190, ORTEC\(®\)) boasting a resolution of 1.7 keV at the 1.33 MeV gamma peak of \(^{60}\)Co. This detector was coupled to a multi-channel analyzer (MCA, MAESTRO-32, ORTEC\(®\)). All recorded radioactivity values underwent meticulous correction, accounting for half-life and decay time considerations.

Under these conditions, 16 elements (Sc, Cr, Fe, Co, Rb, Sb, Cs, La, Ce, Eu, Tb, Yb, Lu, Hf, Th, and U) were examined. To ensure accuracy, concentrations of Ce and La were adjusted, taking into consideration the presence of fission products from \(^{235}\)U (Glascock et al., 1986; Ribeiro Jr. et al., 2013). Lanthanum exhibited negligible discrepancies, while cerium demonstrated minor variations due to the low uranium content in the samples.

The Missouri University Research Reactor (MURR) procedures refer to the use of a specific software, which is written in the GAUSS language and provided by that institution. This software serves to perform statistical analyses, calculating probabilities of sample membership in different clusters via Mahalanobis distance. Elemental concentrations undergo a logarithmic scale transformation for analysis. Additionally, the software facilitates visual representation by generating principal component diagrams, effectively clustering artifacts. Furthermore, it aids in illustrating vectors representing elemental concentrations that delineate cluster boundaries (Glascock, 2021; Guerrero-Rivero et al., 2020; Terreros-Espinosa et al., 2021).

Results and discussion

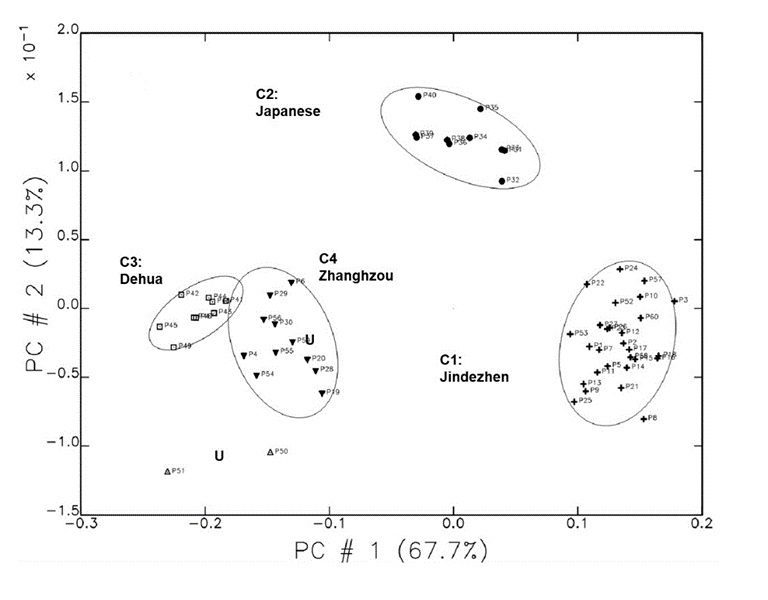

The principal component diagram of the 60-sample assemblage established four separated clusters and two un-clustered samples, shown in Figure 2 and in detail in Table 1. Table 2 displays the mean values and standard deviations of the porcelain bodies.

| C1 (\(n=\)28) | C2 (\(n=\)10) | C3 (\(n=\)9) | C4 (\(n=\)11) | P50 | P51 | |||

| Jingdezhen, CN. | Arita, JP. | Dehua, CN. | Zhangzhou, CN. | |||||

| Sc | 2.8\(\pm\)0.5 | 2.5\(\pm\)0.6 | 4.1\(\pm\)0.6 | 5\(\pm\)1 | 3\(\pm\)0.3 | 4.8\(\pm\)0.5 | ||

| Cr | 4\(\pm\)2 | 4\(\pm\)1 | 9\(\pm\)3 | 12\(\pm\)9 | 8.5 | 16.8 | ||

| Fe (*) | 6.8\(\pm\)0.8 | 4.9\(\pm\)1.2 | 1.5\(\pm\)0.3 | 8\(\pm\)3 | 5.4\(\pm\)0.7 | 3.08\(\pm\)0.04 | ||

| Co | 10\(\pm\)5 | 0.9\(\pm\)0.5 | 1.6\(\pm\)0.5 | 4\(\pm\)2 | 11\(\pm\)1 | 13\(\pm\)5 | ||

| Rb | 407\(\pm\)75 | 189\(\pm\)18 | 230\(\pm\)53 | 250\(\pm\)59 | 521\(\pm\)88 | 277\(\pm\)46 | ||

| Sb | 3.8\(\pm\)1.6 | 4\(\pm\)2 | 0.11\(\pm\)0.07 | 0.4\(\pm\)0.2 | 0.8\(\pm\)0.01 | 0.1\(\pm\)0.01 | ||

| Cs | 48\(\pm\)14 | 10\(\pm\)6 | 2.9\(\pm\)0.5 | 6\(\pm\)0.5 | 3.5\(\pm\)0.06 | 3.5\(\pm\)0.1 | ||

| La | 17\(\pm\)7 | 35\(\pm\)4 | 83\(\pm\)23 | 44\(\pm\)24 | 30\(\pm\)2 | 163\(\pm\)10 | ||

| Ce | 22\(\pm\)5 | 54\(\pm\)5 | 39\(\pm\)14 | 79\(\pm\)30 | 55\(\pm\)1 | 123\(\pm\)3 | ||

| Eu | 0.5\(\pm\)0.2 | 0.4\(\pm\)0.1 | 1.6\(\pm\)0.4 | 2\(\pm\)1 | 1.07\(\pm\)0.02 | 4.04\(\pm\)0.06 | ||

| Tb | 0.5\(\pm\)0.3 | 0.8\(\pm\)0.2 | 1.1\(\pm\)0.6 | 1.7\(\pm\)0.8 | 1.0 | 2.2 | ||

| Yb | 1.7\(\pm\)0.3 | 3.3\(\pm\)0.7 | 7.4\(\pm\)1.8 | 10\(\pm\)7 | 6.2\(\pm\)0.2 | 16\(\pm\)0.5 | ||

| Lu | 0.3\(\pm\)0.05 | 0.4\(\pm\)0.1 | 1.1\(\pm\)0.2 | 1.4\(\pm\)0.9 | 0.84\(\pm\)0.01 | 1.93\(\pm\)0.02 | ||

| Hf | 2.8\(\pm\)0.5 | 3.7\(\pm\)0.5 | 4.8\(\pm\)0.3 | 5\(\pm\)1 | 5\(\pm\)1 | 3.9\(\pm\)0.8 | ||

| Th | 9.5\(\pm\)0.9 | 21\(\pm\)2 | 22\(\pm\)1 | 22\(\pm\)3 | 22\(\pm\)3 | 23\(\pm\)2 | ||

| U | 10\(\pm\)2 | 6\(\pm\)3 | 3.5\(\pm\)0.6 | 5\(\pm\)1 | 4.1\(\pm\)0.1 | 5\(\pm\)0.2 | ||

Among the studied porcelain fragments, distinct compositions emerged in various clusters, Figure 2.

Cluster C1, comprising 28 samples, stood out for its elevated levels of Co, Rb, Sb, and Cs while containing lower concentrations of Cr, rare earth elements (REEs), and Th.

A separate group, Cluster C2, consisting of 10 Japanese samples, was characterized by notably reduced levels of Cr, Co, Rb, and Cs.

Cluster C3, with 9 samples, exhibited low Fe and Sb levels but surprisingly elevated La concentrations, nearly twice that of Ce a departure from Chinese porcelain patterns.

The iron content significantly influences porcelain color; lower concentrations yield a purer white shade in oxidizing firing, while higher levels darken the paste in reducing firing (Li et al., 2011; Li et al., 2011).

Cluster C4, with 11 samples, was characterized by markedly high concentrations of iron and, in contrast, white C3 exhibited a low iron level.

For a visual representation of these clusters and un-clustered samples, refer to Figures 8(a)-(f), which features some photographs.

| (a) | (b) | (c) |

|  |  |

| (d) | (e) | (f) |

|  |  |

The analytical results were compared across data obtained from various porcelain kilns and periods. These included:

samples from Dapu, Jingdezhen, and Zhangzhou kilns (Zhu et al., 2016).

23 specific Chinese samples (Dias et al., 2013).

Chinese artifacts from the Ming, Late Qing, and Qing dynasties (Tripati et al., 2017).

Specimens from Fengdongyan kilns spanning the Early Ming, Middle Ming, and Ming dynasties (Li et al., 2016).

Artifacts from the Yuan and Ming dynasties (Xie et al., 2009).

Four distinct groups from the Song Dynasty (Niziolek, 2015).

Five groups traced back to the Zhangzhou kiln (Ma et al., 2012).

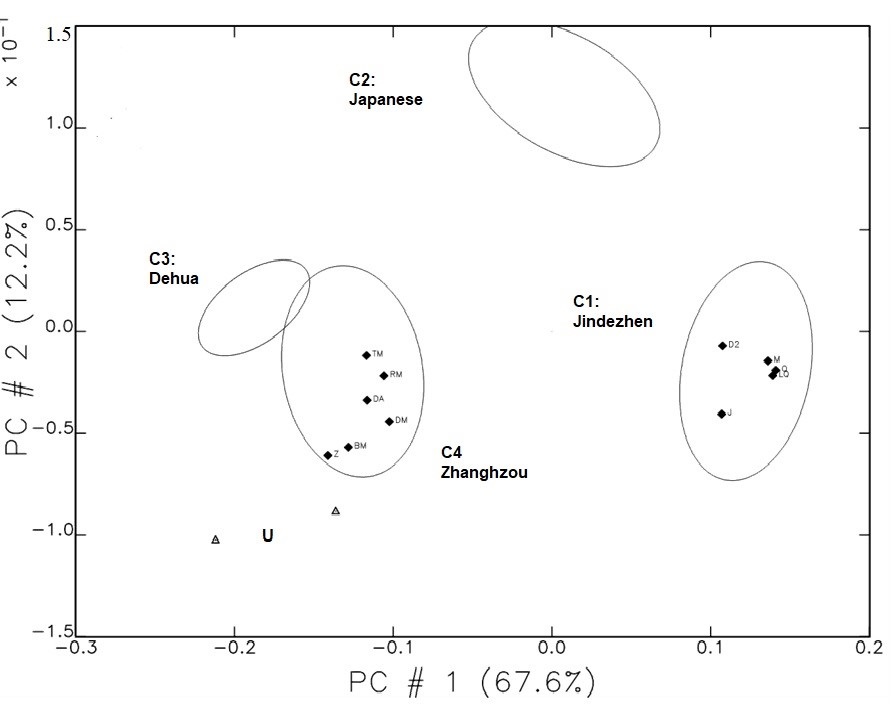

Figure 9 illustrates the principal component diagram constructed with data from 60 specimens, juxtaposed with existing literary data. The figure displays ellipses corresponding to the four clusters alongside both un-clustered samples. Two ellipses include data points from the literature correlating with the information within those ellipses, while the other two ellipses lack literature data, including those of the un-clustered samples.

*\(^1\)Data of the present study. *\(^2\)Adapted from the following studies: *\(^3\)“Tracing the origin of blue and white Chinese Porcelain ordered for the Portuguese market during the Ming dynasty using INAA” by Dias et al., 2013, Journal of Archaeological Science, 40, 3046-3057. *\(^4\)“The provenance of export porcelain from the Nan’ao One shipwreck in the South China” by Zhu et al., 2016, 2016, Antiquity, 90(351), 798-808. *\(^5\)“Chemical composition and provenance of Chinese porcelain shards recovered from Old Goa, west coast of India” by Tripati et al., 2017, Journal of Archaeological Science: Reports, 14, 467-478. *\(^6\)“Provenance of Zhangzhou export blue-and-white and its clay source” by Ma et al., 2012, Journal of Archaeological Science, 39(5), 1218-1226. *\(^7\)“The provenance of export porcelain from the Nan’ao One shipwreck in the South China Sea” by Zhu et al., 2016, Antiquity, 90(351), 798-808.

The elemental composition of C1 bears a striking resemblance to the data associated with blue-and-white porcelains crafted in the renowned Jingdezhen kilns throughout the Ming, Qing, and Late Qing dynasties (Dias et al., 2013; Tripati et al., 2017; Zhu et al., 2016), see Figure 9. Moreover, the findings from C1 align significantly with the white Jingdezhen porcelain records from the Ming Dynasty, as detailed by Xie et al., 2009, exhibiting close correlation across nearly all analyzed elements, apart from some disparities, including lower Fe content and the absence of recorded Cr and Sb concentrations. This comparative analysis, drawn from existing literature, strongly implies that the porcelain specimens represented by C1 were likely crafted within the confines of the Jingdezhen kilns during either the Ming (1368-1644 AP) or the Qing (1644-1912 AP) Dynasties.

The comparison between C2 (Japanese porcelain) and existing literature data was confined to a limited number of elements. In the examination of Japanese porcelain using pXRF (Hsieh & Fischer, 2019), the Fe, Rb, and Th levels closely mirrored those observed in our current research.

While the Fe content values documented for Arita kiln porcelain (Byungsun, 1999) resembled those of C2, there were no other matching elements between their study and ours. Therefore, these data were not included in Figure 9.

The elemental composition of the blue-and-white porcelain in C4 exhibited a significant resemblance to the Zhangzhou porcelain data reported in previous studies (Ma et al., 2012), Figure 9. In addition, the Fe, Rb, and Th concentrations obtained from the pXRF analysis of Zhangzhou porcelain by Fischer & Hsieh, 2017 were consistent with our findings. Therefore, it is inferred that the C4 samples were produced in the Zhangzhou kilns. On the contrary, there is no matching porcelain data in the existing literature to corroborate the origin (allegedly Zhangzhou) of the un-clustered samples (P50 and P51), leaving their source undetermined.

Cluster C3 comprises white porcelain pieces characterized by high rare earth element (REE) content and low levels of iron (Fe), resulting in a lack of color in the material. Thus, the white Dehua samples in this collection achieved a particularly pristine white hue. Numerous studies in the literature have examined Dehua porcelain using EDXRF (spectrometry) (Juan et al., 2007; Leung & Luo, 2000; Leung et al., 2000; Li et al., 2011; Li et al., 2011; Zhou et al., 2019). The data from these analyses do not necessarily align with the findings presented in this study using INAA, which is why those data were not included in Figure 4. Interestingly, one of these reports, Li et al., 2011 observed periodic decreases in ferric oxide content in Dehua porcelains across the Yuan (1280–1368 AP), Ming (1368–1644 AP), and Qing Dynasties (1644–1912 AP). Considering the timeline, it is plausible that the C5 specimens, produced in the Dehua kilns during the late Ming and Qing Dynasties, might have reached Mexico City between the late 17th and early 18\(^{th}\) centuries. Several elements in C3 also share similarities with a collection of 11 Dehua and three Jingdezhen porcelain artifacts retrieved from the Java Sea shipwreck dating back to the Song Dynasty (960-1279) (Niziolek, 2015). While this chronology does not agree with New Spain (16\(^{th}\) to 19\(^{th}\) centuries), the chemical composition of the Dehua porcelain pieces does.

Porcelain items from the Ming and Qing dynasties were amassed between the 16\(^{th}\) and 18\(^{th}\) centuries. They were in large quantities acquired by individuals belonging to various European monarchies or the high nobility, who curated splendid collections. These collections were widely regarded as symbols of opulence, authority, and prestige (Tian, 2020).

Historically, the arrival of foreign goods had a transformative effect on the economy, culture, and artistic traditions of people (Tripati et al., 2017). Chinese and Japanese porcelain arrived at Manila port in the Philippines in exchange for silver from New Spain, facilitated by the Nao de China trade route. Subsequently, these goods journeyed to Acapulco, becoming central to a bustling trade fair. From there, they were transported by mule to the capital of New Spain and other cities, including Veracruz, before continuing on to Spain.

Research by Carrera, 1959 illustrates how opulent Chinese items became commonplace in Spanish residences, churches, convents, and other prominent settings. The high cost of porcelain, surpassing that of other ceramics, cemented its status as a symbol of prestige, reflecting social and economic standing. Silver from New Spain played a crucial role in supporting this trade. This is evident throughout the Viceroyalty period (Fournier, 1990; Fournier & Otis Charlton, 2015; Junco & Fournier, 2008). Significantly, the impact of Chinese porcelain designs played a crucial role in shaping the evolution of the Talavera ceramic style in Puebla, among various others. Throughout history, the introduction of foreign goods has had a transformative effect on the economy, culture, and artistic traditions of communities.

According to research by Carrera, 1959 trade between the Philippines and New is, opulent Chinese items became commonplace in Spanish residences, churches, convents, and other prominent places. The steep prices of porcelain, especially, surpassed those of other ceramics, establishing itself as a symbol of prestige for owners, mirroring their social and economic status. Silver from New Spain played a pivotal role in supporting this trade. This pattern was observable across the Viceroyalty period (Fournier, 1990; Fournier & Otis Charlton, 2015; Junco & Fournier, 2008). Significantly, the impact of Chinese porcelain designs played a crucial role in shaping the evolution of the Talavera ceramic style in Puebla, among various others. Throughout history, the introduction of foreign goods has had a transformative effect on the economy, culture, and artistic traditions of communities.

In Mexico, porcelain or other objects have been found and documented that appear in inventories usually with the general qualifier “from China” and the same thing happens in the data of those merchandise that left Veracruz for Spain (Curiel, 2013). Possibly not all these goods were from China, but from other Asian countries; some of these objects may not have arrived via the Nao of China through the Pacific Ocean but instead could be imitations produced in other countries, particularly in Europe, and arrived via Veracruz. Examples of such imitations include ceramics and fine crystals with Asian designs. Hence, it is crucial to conduct research that can help identify the origins of these objects, providing insights into the social and cultural contexts of their creation, irrespective of the time and location. A reliable method for tracing the origins of archaeological materials, such as the porcelains examined in this study, is through precise techniques like neutron activation analysis, which can determine the content of trace elements.

Analysis of the collection’s samples through methods like INAA and statistical analysis unveiled noteworthy differences in their chemical makeup. These discrepancies proved instrumental in pinpointing the origin of the specimens, shedding light on the intricate commercial past of porcelain in New Spain. Such precise archaeometric measurements were essential to achieving this investigative goal.

Conclusions

The blue-and-white pieces in cluster C1 originated from the Jingdezhen kilns during the late Ming (1368–1644 AP) and/or Qing (1644–1912 AP) Dynasties. A separate set of blue-and-white items, Cluster C4, highlighted distinct characteristics divergent from Jingdezhen kiln products, bearing similarities to porcelains crafted in the Zhangzhou kilns. These specimens showed reduced levels of Sb and Cs, but elevated quantities of iron and rare earth elements compared to those originating from the Jingdezhen kilns.

The chemical composition of Japanese blue-and-white porcelain differs from its Chinese counterparts. Specifically, the Japanese pieces exhibit lower levels of cobalt, rubidium, and cesium compared to other blue-and-white porcelain pieces within the same collection. While only a few elements were compared based on available literature data, these specimens originated from the Arita kilns during the 17\(^{th}\) and 18\(^{th}\) centuries.

To the best of our knowledge, prior to this study, no nuclear activation analyses had been conducted on Chinese Dehua or Japanese Arita porcelains. This groundbreaking research unveiled the presence of sixteen chemical elements, primarily in trace amounts, offering valuable insights for the identification of these specific types of porcelain.

Comparatively, the iron content in Dehua white porcelain is notably lower than that found in blue-and-white porcelain. The white porcelain pieces within the current collection are highly likely to have originated from the Dehua kilns and were transported to Viceregal Mexico City during the late Ming and Qing Chinese Dynasties.

The present study provides insight into the trade of consumer goods, specifically porcelain, during the Viceroyalty period in Mexico City. Furthermore, it reinforces the evidence of the continuous and important trade of both China and Japan with New Spain using the Nao of Chine. Other relevant aspect is to offer analytical data on some types of porcelain that were not available until now and that will be useful later for their identification.

Author contributions

E. Terreros-Espinosa participated in: Conceptualization, supervision, and writing. M. Jiménez-Reyes and D. Tenorio participated in: Conceptualization, Formal analysis, Methodology Validation, preparation of the original draft, and editing. S. de la Vega-Doria participated in: Conceptualization and editing.

Conflicts of interest

The authors certify that there is not a commercial or associative interest that represents a conflict of interest in relation to the manuscript.

Acknowledgments

The authors express their gratitude to the Programa de Arqueología Urbana and the Templo Mayor-Programa de Mejora de la Gestión (Instituto Nacional de Antropología e Historia, Mexico) for supplying samples of ancient Chinese and Japanese specimens. The authors appreciate the technical support from Nuclear Reactor staff and Mr. Jesús Muñoz Lujano. Special thanks are extended to the anonymous reviewers for their insightful suggestions for this manuscript.

References

Byungsun, B. (1999). White Porcelain Production Techniques in the Late Chosǒn Dynasty. 249--287.

Carrera Stampa, M. (1959). La Nao de la China. 9(1), 97--118.

Curiel Méndez, G. (2013). De primores curiosidades y maravillas del Oriente. In A. Fernández Torres, & A. Sánchez de Mora. (Coords.), Pacífico, España y la aventura de la Mar del Sur: Archivo General de Indias (pp. 275-293). Acción Cultural Española. .

Cheng, L., Feng, X-q., Feng, S-l., Cheng, H-s., Jaksicc, M., Fan, Ch-S. & Zhang, W-J. (2004). PIXE Analysis of Ancient Chinese Porcelain of Hutian Kiln. In Proceedings. 10^th Conference on Particle-Induced X-ray Emission and its Analytical Applications PIXE, Portorož, Slovenia.

Cheng, H. S., Zhang, Z. Q., Xia, H. N., Jiang, J. C. & Yang, F. J. (2002). Non-destructive analysis and appraisal of ancient Chinese porcelain by PIXE. 190(1/4), 488--491.

Dias, M. I., Prudêncio, M. I., De Matos, M. P. & Rodrigues, A. L. (2013). Tracing the origin of blue and white Chinese Porcelain ordered for the Portuguese market during the Ming dynasty using INAA. 40(7), 3046--3057.

Dillon, M. (2008). Transport and marketing in the development of the Jingdezhen porcelain industry during the Ming and Qing dynasties. In M. Dillon (Org.), Chinese Economic History up to 1949 (Vol. 1, pp. 540-552).

Fischer, C. & Hsieh, E. (2017). Export Chinese blue-and-white porcelain: compositional analysis and sourcing using non-invasive portable XRF and reflectance spectroscopy. 14--26.

Fournier, P. (1990). Evidencias Arqueológicas de la Importación de Cerámica en México, con Base en los Materiales del Ex-convento de San Jerónimo. Instituto Nacional de Antropología e Historia.

Fournier, P. & Otis Charlton, C. (2015). De China a la cuenca de México: consumo suntuario de porcelanas de las dinastías Ming y Qing en ranchos y haciendas del área de Otumba. Universidad de Tamkang. 31--42.

Fournier, P. & Junco Sanchez, R. (2019). Archaeological Distribution of Chinese Porcelain in Mexico. Springer. 215--237.

Glascock, M., Nabelek, P., Weinrich, D. & Coveney, R. (1986). Correcting for uranium fission in instrumental neutron activation analysis of high-uranium rocks. 121--131.

Glascock, M. D. (2021). MURRAP User Guide.

Guerrero-Rivero, S., Tenorio, D., Jiménez-Reyes, M., Junco-Sánchez, R. & López-Reyes, M. C. (2020). Commercial interaction at the port of Acapulco, Mexico, during the Viceregal period: A provenance study of ceramic containers and regional wares. 1--14.

Hsieh, E. & Fischer, C. (2019). Japanese or Chinese? Non-invasive analysis of East Asian blue-and-white porcelain. 5483--5497.

Juan, W., Leung, P. L. & Jiazhi, L. (2007). A study of the composition of Chinese blue and white porcelain. 52(3), 188--198.

Junco, R. & Fournier, P. (2008). Del celeste imperio a la Nueva España: importación distribución y consumo de la loza de la China del periodo Ming Tardío en el México virreinal. Universidad de Tamkang. 3--22.

Katsuki, H., Chang, K. H., Kang, M. H., Lee, W. J., Lee, J. H., Kim, U. S., Han, K. S., Kim, J. H., Cho, W. S. & Hwang, K. T. (2019). Comparative study on old white porcelains produced in Gwangju (Korea) and Arita (Japan) in the 15th to 19th centuries. 1--8.

Kerr, R. & Ayers, J. (2002). Blanc de Chine: History and Connoisseurship Reviewed. Routledge.

Kuwayama, G. (1997). Chinese Ceramics in Colonial Mexico. University of Hawaii Press.

Leung, P. L. & Luo, H. A. (2000). Study of provenance and dating of ancient Chinese porcelain by x‐ray fluorescence spectrometry. 29(1), 34--38.

Leung, P. L., Peng, Z. C., Stokes, M. J. & Li, M. T. (2000). EDXRF studies of porcelains (800–1600 AD) from Fujian China with chemical proxies and principal component analysis. 29(3), 253--259.

Li, W., Luo, H., Li, J., Lu, X. & Guo, J. (2011). The white porcelains from Dehua kiln site of China: Part I Chemical compositions and the evolution regularity. 37(1), 355--361.

Li, W., Luo, H., Li, J., Lu, X. & Guo, J. (2011). The white porcelains from Dehua kiln site of China. Part II: Microstructure and its physicochemical basis. 37(2), 651--658.

Li, L., Huang, Y., Sun, H. Y., Yan, L. T., Feng, S. L., Xu, Q. & Feng, Q. X. (2016). Study on the property of the production for Fengdongyan kiln in Early Ming dynasty by INAA and EDXRF. 52--57.

Ma, H., Zhu, J., Henderson, J. & Li, N. (2012). Provenance of Zhangzhou export blue-and-white and its clay source. 39(5), 1218--1226.

Mejia, J. & Mejia, J. (2022). The economics of the Manila Galleon. 15(1), 35--62.

Min, L. (2013). Fragments of globalization: Archaeological porcelain and the early colonial dynamics in the Philippines. 52(1), 43--74.

Nagatake, T. (2003). Classic Japanese Porcelain: Imari and Kakiemon. Kodansha International.

Niziolek, L. C. A. (2015). A compositional study of a selection of Song dynasty Chinese ceramics from the Java Sea Shipwreck: Results from LA-ICP-MS analysis. 48--66.

Priyadarshini, M. (2018). Chinese porcelain in colonial Mexico: the material worlds of an early modern trade. Springer Nature Switzerland.

Ribeiro Jr., I. S., Genezini, F. A., Saiki, M. & Zahn, G. S. (2013). Determination of uranium fission interference factors for INAA. 759--762.

Shakhashiro, A., Trinkl, A., Törvenyi, A., Zeiller, E., Benesch, T. & Sansone, U. (2006). Report on the IAEA-CU-2006-06 proficiency test on the Determination of Major Minor and Trace Elements in Ancient Chinese Ceramic. International Atomic Energy Agency.

Sterba, J. H., Mommsen, H., Steinhauser, G. & Bichler, M. (2009). The influence of different tempers on the composition of pottery. 36(7), 1582--1589.

Takenori, N. & Terreros-Espinosa, E. (2020a). Ceramics in Guadalajara Mexico. 141--154.

Takenori, N. & Terreros-Espinosa, E. (2020b). Imari Porcelain Crossing the Pacific Ocean. 50--51.

Terreros-Espinosa, E., Tenorio, D. & Jiménez-Reyes, M. (2021). Pre-hispanic pottery from the Zoque area of Tabasco, Mexico: Provenance implications. 1--16.

Terreros-Espinosa, E., Tenorio, D. & Jiménez-Reyes, M. (2021). Botijas y peruleras en la Ciudad de México Colonial: Un estudio arqueométrico. 30(2), 340--355.

Tian, Ch. (2020). Porcelanas chinas de la Dinastía Qing (1644 -1912) en la colección Federico Torralba (Museo de Zaragoza).

Tripati, S., Parthiban, G., Pattan, J. N. & Menezes, A. (2017). Chemical composition and provenance of Chinese porcelain shards recovered from Old Goa, west coast of India. 467--478.

Wu, J., Leung, P. L., Li, J. Z., Stokes, M. J. & Li, M. T. (2000). EDXRF studies on blue and white Chinese Jingdezhen porcelain samples from the Yuan, Ming and Qing dynasties. 29(3), 239--244.

Xie, G., Feng, S., Feng, X., Li, Y., Han, H., Wang, Y., Zhu, J., Yan, L. & Li, L. (2009). Study on the elemental features of ancient Chinese white porcelain at Jingdezhen by INAA. 267(5), 821--824.

Zhu, J., Ma, H., Li, N., Henderson, J. & Glascock, M. D. (2016). The provenance of export porcelain from the Nan'ao One shipwreck in the South China Sea. 90(351), 798--808.

Zhou, Y., Wang, K., Jin, Y., Sun, J., Cui, Y. & Hu, D. (2019). Chemical and microstructural comparison of the export porcelain from five different kilns excavated from Nanhai I shipwreck. 45(10), 12880--12887. https://doi.org/10.1016/j.ceramint.2019.03.211